The 168 hp 544 G-Tier with 2.75–3.00 cubic yard bucket provides hand front-end features and plenty of productivity-boosting enhancements.

products images and videos

The 168 hp 544 G-Tier with 2.75–3.00 cubic yard bucket provides hand front-end features and plenty of productivity-boosting enhancements.

Customers can choose between pin-on bucket options as well as Hi-Vis/ISO and JRB style couplers that accept both K and L-series and Performance Tiering buckets and attachments.

The cab on the 544 G-tier was designed to provide different levels of comfort to operators depending on the machine application. The setup ensures that operation of the machine is straightforward with easy to access machine settings and features.

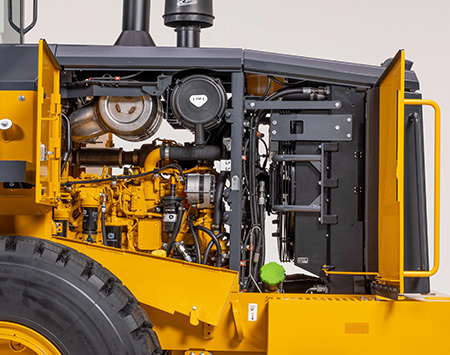

The 544 G-tier is backed by John Deere’s world class dealer network that provides warranty support, maintenance, and has the parts on the shelf needed to allow maximum uptime. Attributes related to servicing and supporting the 544 G-tier are no different than those experienced today on all other models of John Deere equipment.

The 544 G-tier wheel loader was designed to provide an economical solution to the market, without having to sacrifice on the known productivity that John Deere loaders are known for

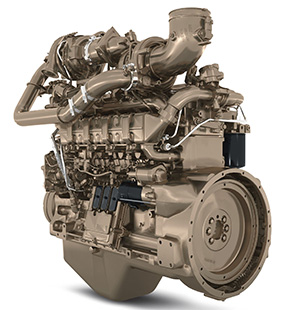

Built on over 50 years of experience producing and supporting wheel loaders, the 544 G-tier features a high commonality of components found in other Deere loaders that are designed and tested to meet John Deere Standards including the engine, transmission, and axles.

The 544 G-tier controls were designed with operators of all skillsets in mind. The simple setup and functionality means operators can put the machine to work quicker and easier.

"*" indicates required fields

"*" indicates required fields