The 26G is a 2.7-metric ton excavator that offers versatility and maneuverability. This reduced-tail-swing excavator is perfect for narrow workspaces.

products images and videos

The 26G is a 2.7-metric ton excavator that offers versatility and maneuverability. This reduced-tail-swing excavator is perfect for narrow workspaces.

Think of changing attachments as a system. With the quick connect auxiliary couplers and the manual quick coupler for attachments, changeover to the next attachment is quick with minimal downtime. When using hydraulic attachments, the auxiliary selector valve lets you quickly choose between attachment one-way and two-way flows.

Make a sizable impact on your productivity and profitability with the backfill blade. The backfill blade can be used to level and backfill trenches. It is the same width as the undercarriage width. The blade can add versatility by using the blade and bucket to clamp and carry pipe, rocks, or other bulky items. A bolt-on cutting edge is available as optional equipment for the backfill blade.

With large entryways and virtually unrestricted sightlines, the G-Series’ spacious operator stations deliver all the comfort, convenience, and visibility operators need to bring out their best. Their ergonomically designed operator stations are built to accommodate even larger operators.

Extended maintenance intervals enable the machine to remain working for longer periods of productive work before the need to service. This greatly increases uptime and productivity of the unit. Hinged door provides wide-open access to the side-by-side oil cooler, radiator, as well as battery. Cooler design resists trash buildup and allows easier core cleanout. Access is quick and convenient.

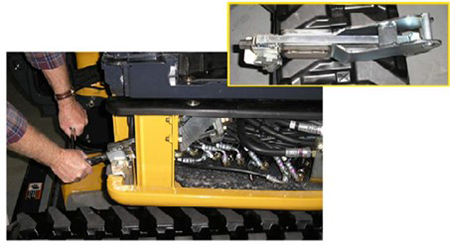

An optional tilt tool is available for tilting the cab or canopy.

When maintenance or repair is required, simply use the tilt tool to raise the cab forward to an industry leading 50 degrees. This allows easy access to many components under the floor.

The X-frame undercarriage is similar to that of larger excavators, and it is designed to shed dirt and debris from the track frames. A track adjuster is located in each track frame and can be adjusted using a standard high pressure grease gun.

"*" indicates required fields

"*" indicates required fields