Build your own 903M Tracked Feller Buncher, download a brochure, and compare Deere to competitive feller bunchers.

products images and videos

Build your own 903M Tracked Feller Buncher, download a brochure, and compare Deere to competitive feller bunchers.

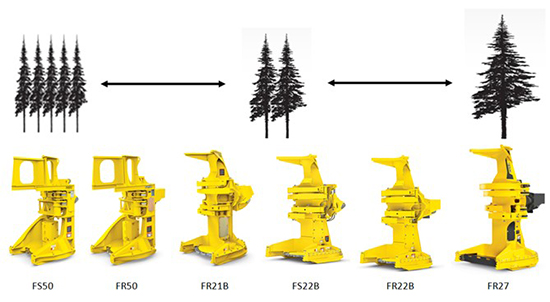

From small stems to big timber, softwood to hardwood, level or sloped ground, John Deere has a disk saw felling head that’s designed for your job. The new FR27 boasts our highest single-cut-capacity, with over 16 percent more accumulation area than the FR24B, making it an excellent choice for large timber. Delivering efficient, multi-stem high-accumulation performance with huge pocket and tall horns, the FS50 and FR50 felling heads are best suited for thinning and high-production plantation harvests. For more versatile applications, the FS22B and FR22B heads are robust enough to handle large trees, with the tree-handling performance to also efficiently accumulate mid-sized timber. If lightweight is a must, the FR21B is our lightest, high-rotation head that is optimized for small to mid-sized timber.

| Model | FS50 | FR50 | FR21B | FS22B | FR22B | FR27 |

| Cut Capacity | 510 mm (20.0 in.) | 545 mm (21.5 in.) | 559 mm (22.0 in.) | 690 mm (27.2 in.) | ||

| Accumulation Area | 0.64 m2 (6.9 sq ft) | 0.46 m2 (5.0 sq ft) | 0.48 m2 (5.2 sq ft) | 0.70 m2 (7.5 sq ft) | ||

| Ideal Timber Range | 150-350 mm (6-14 in.) | 250-460 mm (10-18 in.) | 300-500 mm (12-20 in.) | 460-660 mm (18-26 in.) | ||

| Typical Application | Plantation, thinning, and select cut | Select cut and final felling | Select cut and final felling | Final felling and swamp logging (swell) | ||

| Typical Operation | High accumulation Short-to-mid-height timber |

Mid-to-high accumulation Mid-height timber |

Mid accumulation Mid-to-tall-height timber |

Mid-to-low accumulation Tall timber |

||

| Weight | 3,370 kg (7,430 lb.) | 3,660 kg (8,070 lb.) | 3,140 kg (6,920 lb.) | 3,550 kg (7,830 lb.) | 3,840 kg (8,470 lb.) | 4,250 kg (9,370 lb.) |

| Wrist Rotation |

30 degrees | 312 degrees | 302 degrees | 30 degrees | 312 degrees | 295 degrees |

Felling head specs

Operating for long hours is common. As the day goes on, maintaining consistent productivity is important. One factor in keeping high, consistent productivity is a comfortable operating environment. The M-series boasts greatly increased window area for better visibility and more cab space over prior models. Low-effort electrohydraulic (EH) controls allow you to customize the button and lever layout to your preference and save your settings when switching between operators.

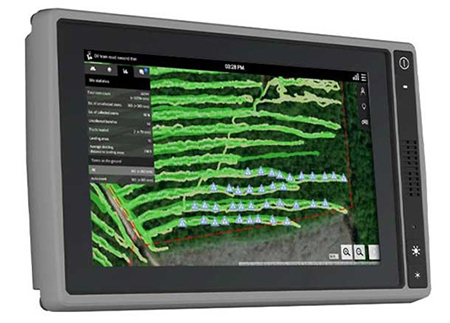

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

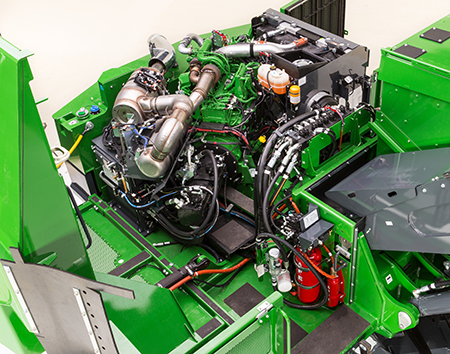

Easy access to service components helps operators perform daily checks and any scheduled maintenance, which helps minimize unplanned downtime and costly repairs down the road. The 900M-series tracked machines feature a fully opened enclosure and service doors for excellent access to all scheduled maintenance areas.

*Side walkways are optional features on 903M, 953M, and 953MH models

The M-series undercarriage is purpose built to handle severe forestry applications while maintaining maneuverability, especially in thinning operations. The track frames are shaped to deflect debris while also providing strength and stability.

"*" indicates required fields

"*" indicates required fields